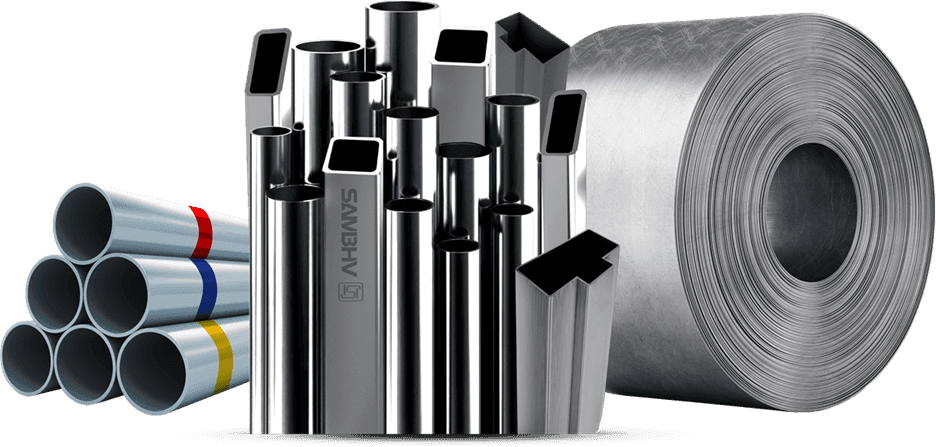

Stainless Steel CR Coils

Overview

At our upcoming facility in Village – Kuthrel, District Raipur, Chhattisgarh, we will introduce Stainless Steel Cold Rolled (SS CR) Coils, a value-added product created by cold rolling of stainless steel HRAP (Hot Rolled Annealed Pickled) coils. The cold rolling process, performed at room temperature, not only enhances the surface finish but also significantly improves the mechanical properties of the coils, such as strength, ductility, and precision. This makes them ideal for industries requiring high-performance materials that prioritize precision, durability, and reliability. The cold rolling process also results in tighter dimensional control, ensuring that the coils meet exacting industrial standards.

We plan to cater to the growing demand for stainless steel products by selling a significant portion of our SS CR coil production to key sectors, including stainless steel pipe manufacturing, utensil production, and other industrial applications where superior surface finish and mechanical strength are critical. This strategic expansion will allow us to serve a wider range of industries and markets more effectively, enabling us to meet diverse customer needs while driving profitability through superior product offerings. Additionally, our investment in advanced manufacturing technology at this facility will ensure that we maintain a competitive edge in producing premium-grade SS CR coils.

Key Features

- Superior Surface Finish: Our cold rolling process imparts a smooth, polished surface, enhancing both the appearance and performance of the SS CR coils. This feature makes the product ideal for industries where aesthetics and precision are equally important, such as the manufacturing of stainless steel kitchenware and decorative applications.

- Increased Strength: The cold rolling process significantly improves the mechanical properties of the coils, making them ideal for high-strength applications. This increased strength is crucial in sectors like construction, where durability and load-bearing capacity are required.

- Precision and Tolerance: Tighter dimensional tolerances ensure consistent quality and reliability for demanding industrial uses, where exact specifications are essential to the product’s performance. This precision ensures that our coils meet the high standards expected by industries such as automotive, aerospace, and heavy machinery.

With this new facility, we will not only increase our production capacity but also expand our market presence by offering value-added products that meet the ever-evolving needs of our customers.

Get Detailed Information

Explore the technical specifications of all our products for details of features, dimensions, materials, and performance. Get all the information you need before making a purchase

| Coil Width | As per requirement |

| Thickness range | 0.26 mm to 2.5 mm |

| Coil OD | Upto 1800 mm |