Stainless Steel HR Coils

Stainless Steel HR Coils

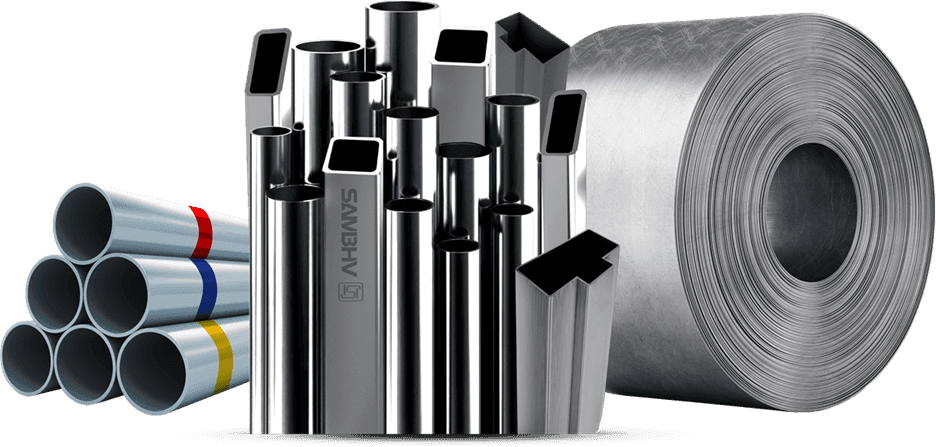

At our Sarora facility, with an installed capacity of 60,000 MTPA, we specialize in producing Stainless Steel Hot Rolled (HR) Coils. The HR coil manufacturing process involves deforming stainless steel blooms/slabs at high temperatures and applying precise roll pressure. The material is passed through a series of rolls with pre-set gaps, pressure, and speeds to achieve its final dimensions, while maintaining high temperatures throughout the process. This continuous deformation under elevated temperatures ensures optimal metallurgical properties and uniform thickness, which is critical for high-performance applications in various industries.

Manufacturing Process

Our advanced hot rolling mill, equipped with Hydraulic Automatic Gauge Control (HAGC) technology, ensures that the rolling process is conducted with maximum precision. This cutting-edge technology allows us to roll stainless steel blooms/slabs as well, guaranteeing that each HR coil is produced with precise control over both the thickness and surface quality. This advanced process not only enhances the mechanical properties of the material but also improves the overall performance and durability of the coils.

In addition to our in-house requirements, our stainless steel HR coils are tailored to meet the diverse specifications of various industrial clients. The majority of our in-house HR coils (stainless steel) will be used to manufacture SS HRAP coils and SS CR coils, which are vital components in industries such as construction, infrastructure, and manufacturing. These stainless steel HR coils are highly sought after for their corrosion resistance, strength, and versatility in multiple industrial applications.

Get Detailed Information

Explore the technical specifications of all our products for details of features, dimensions, materials, and performance. Get all the information you need before making a purchase

| Coil Width | 37 to 300 mm |

| Thickness range | 2.0 mm & above |

| Coil OD | Upto 1800 mm |